About Us

A technology company committed to traffic and road safety solutions, stand as engineering excellence, innovation and reliability. We are providers of Intelligent Transportation System, Electronic Toll Collection, Weight Enforcement and Traffic telematic solutions, Smart urban mobility, Smart City Module, Check Post automation, Smart Parking Solution, Traffic Safety and security and weight Digital Transportation engineering enforcement.

As a one stop solutions providers, Tollman offers end-to-end solutions covering the entire value creation chain of its customers, from components and design to the implementation and operation of system.

We have always believed in developing long term relationships with our clients and working together to deliver creative solutions in the building business. We are committed to engineering excellence & innovation with an aim to provide Simple Solutions for Complex Connections driven by the philosophy of "There's no good idea that can't be improved on" and we take great pride in standing behind in playing an equal role and contributing to our customer's long-term success.

Work Areas

- Advance Traffic Management System

- Hybrid Toll Management System

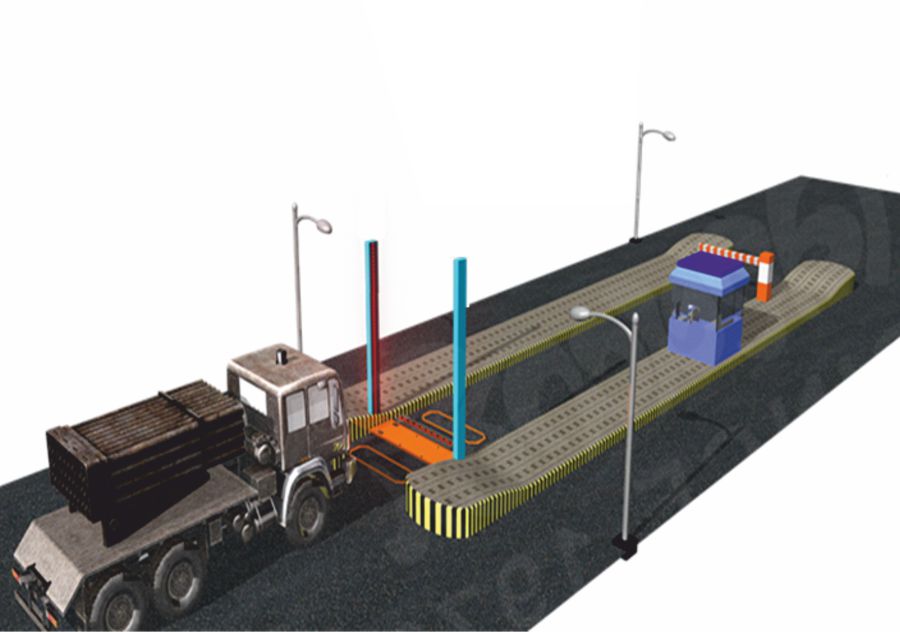

- Check Post Automation

- Check Post Automation

- Weight Based Tolling Solution

- Intelligent Transportation System

- Urban Traffic Management System

- Smart City Modules